Software Projects

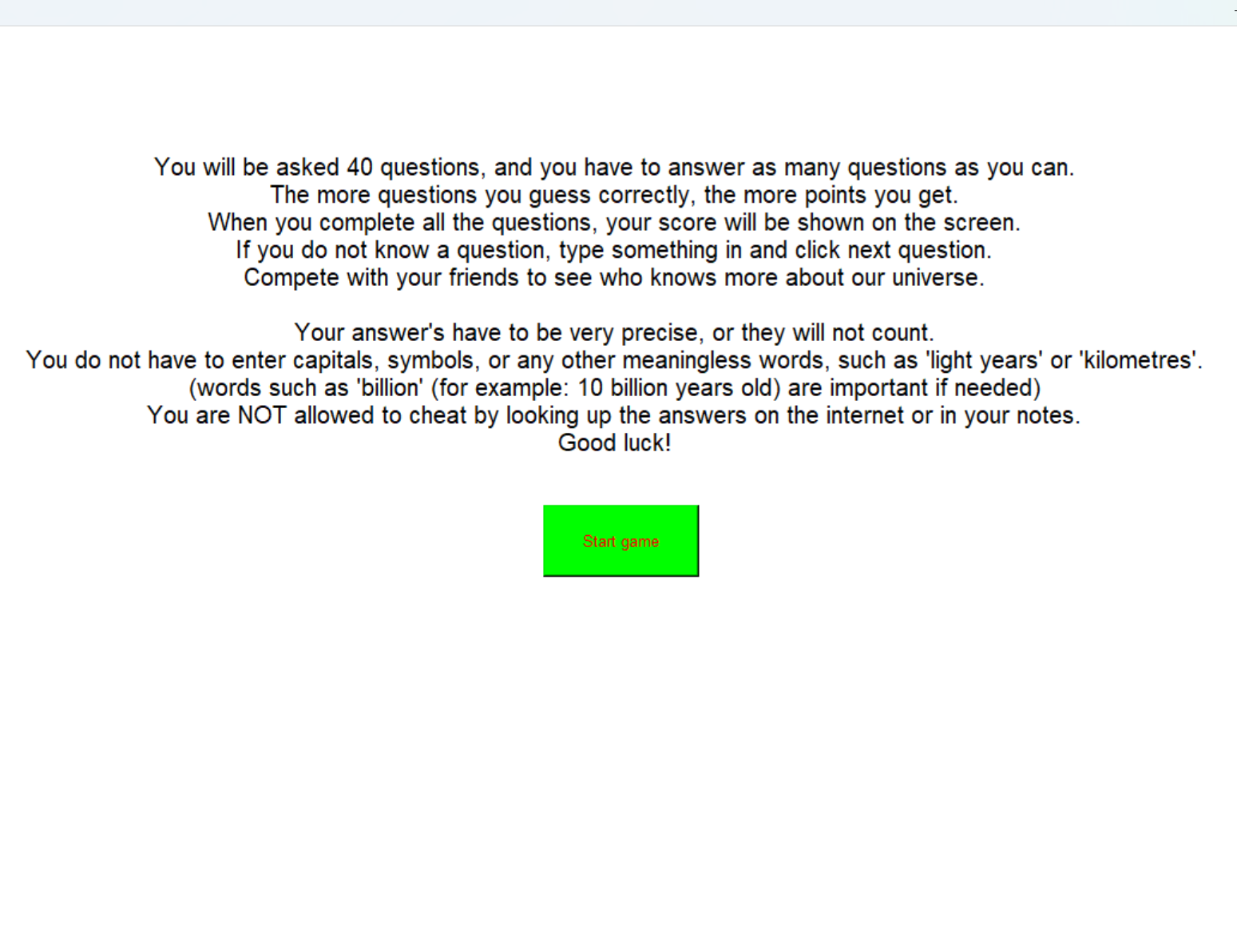

Astronomy Game

May, 2017

I began learning coding with Python, which I used to make a bunch of little games. One of the games is an astrology quiz game, which I used as a science project.

This is a JavaScript remake of the original Python code, so you can actually try it out!

Just click the rules button and see how well you can do.

The original Python code opened a new window to play in, which was something I had just started learning

at the time. It was a fun idea I came up with to use as a

science project,

and it turned into a fun class trivia contest.

If you're curious, you can view the original code

and download the files to try it out yourself.

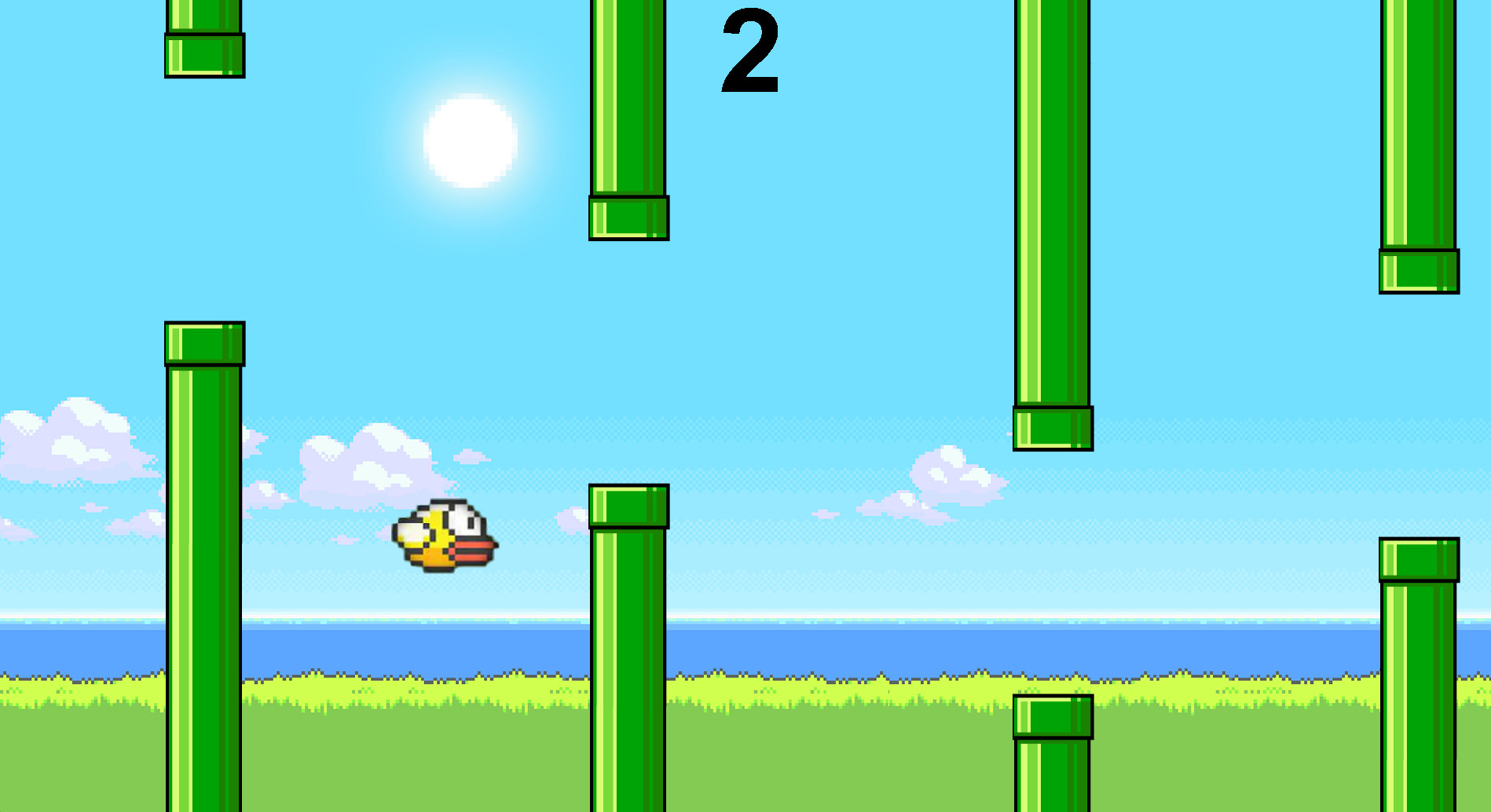

Flappy Bird

May, 2023

After learning the basics of the java programming language in grade 11, the final project in the course was to create a game using everything that we learned. I chose to make a recreation of flappy bird with a 2-player feature.

My first high school computer science class was all about learning the basics of

coding, logic, and graphics

through Java. At the end of the course, each student

created their own game using what we had learned in class.

When the game is launched, the user is met with a title screen that gives 3 options —

play the game with one or two players or read the rules. The single-player option works

exactly like the original popular Flappy bird game, where the player uses a key to fly a bird through

pipes as long as possible, including the score and even sound effects.

The multi-player is a twist on the game, where two people could play simultaneously and the player

who lasts the longest is the winner.

If you want to try the game out yourself, you can find the game files here

and run it in a Java IDE.

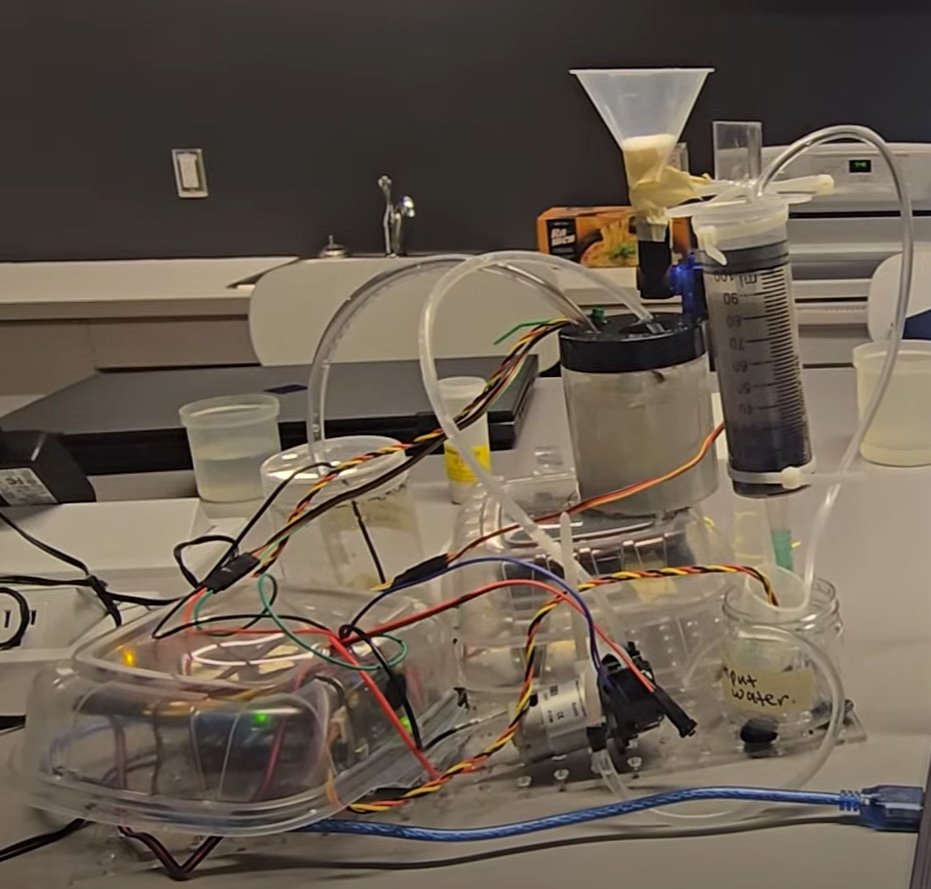

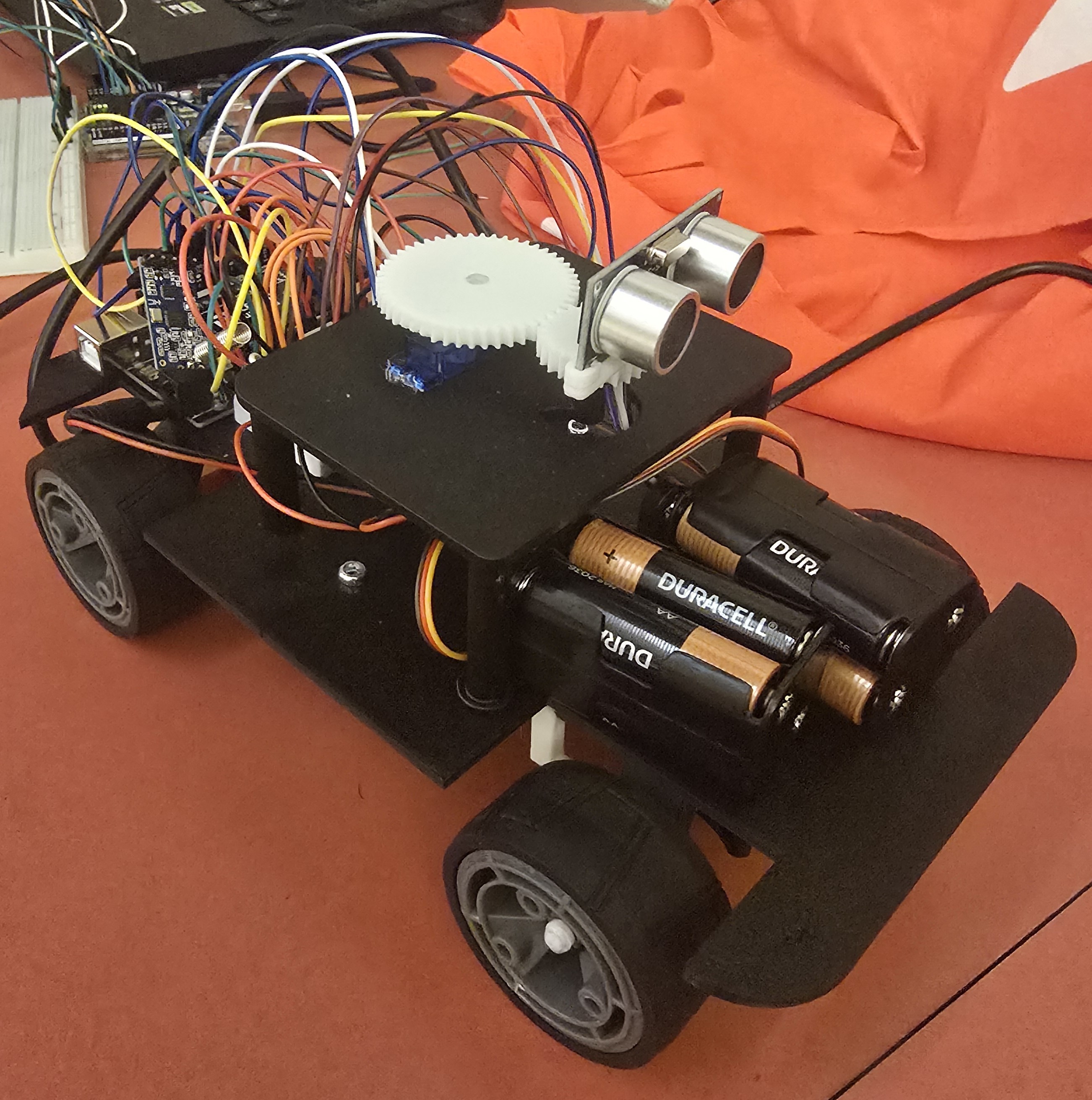

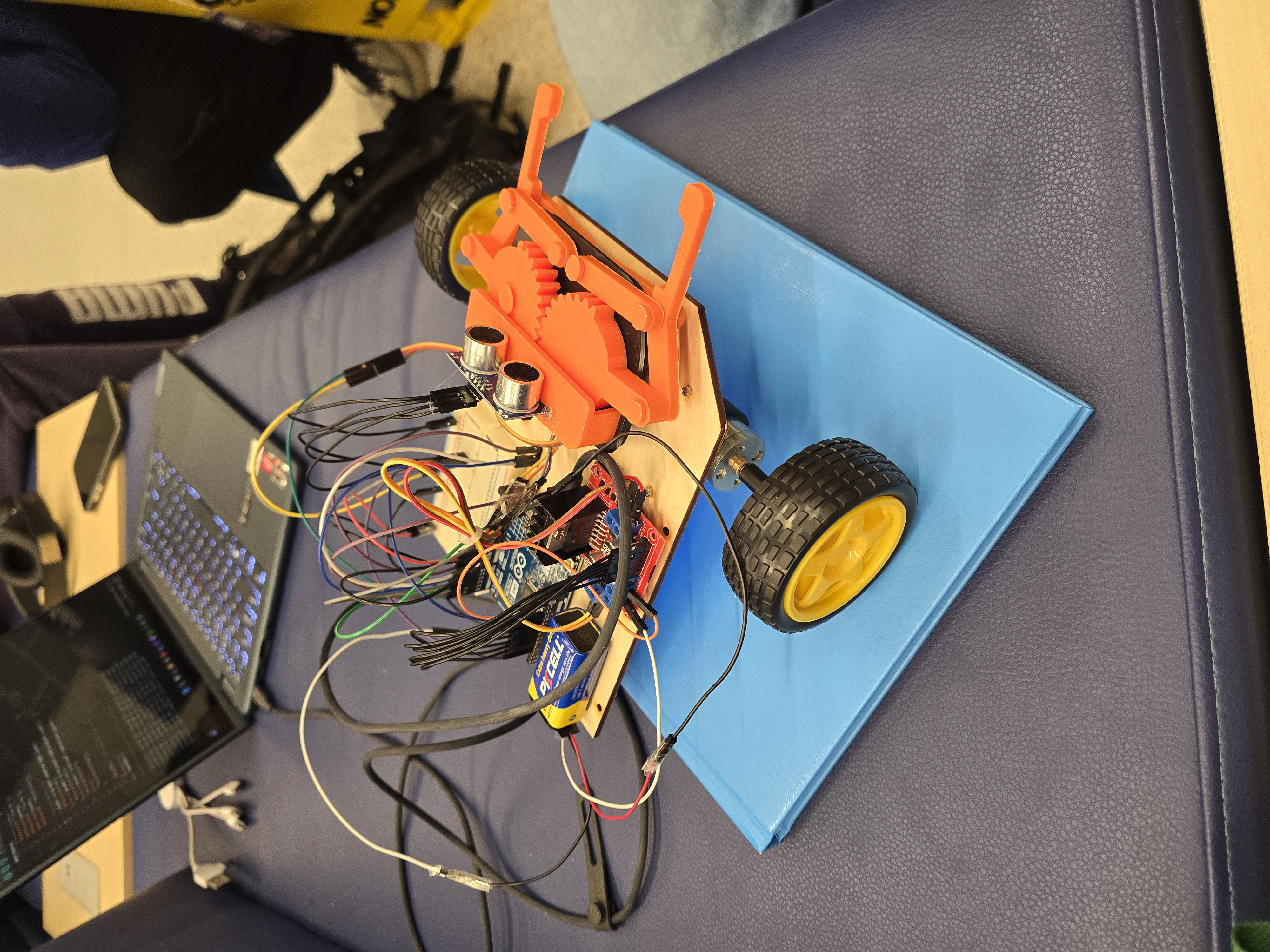

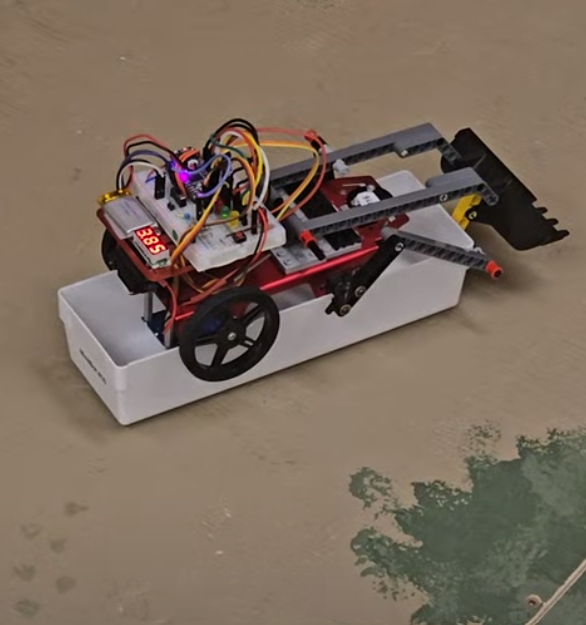

Mini-bot

March, 2025

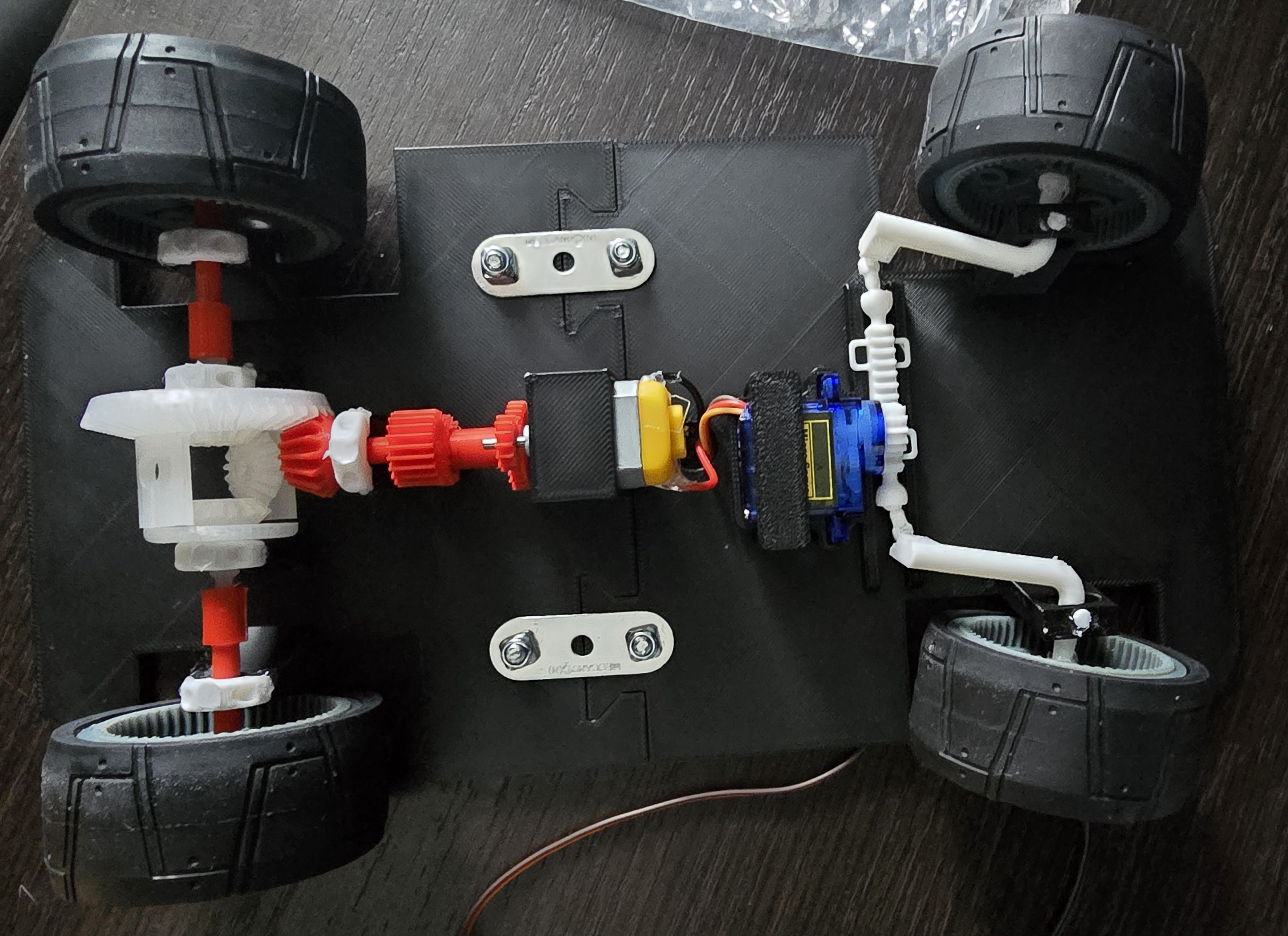

Throughout my Mechatronics and Robotics Design 1 course, we were tasked with programming a mini-bot to perform certain tasks. For example, it needed to be able to follow a line or pick up / drop items from one location to another.

This project spanned 6 weeks, during which each group learned and practiced coding bots

using Arduino software and

hardware components.

We learned how to use different sensors, such as distance sensors and colour sensors, as well as how to control servo motors

for the wheels and bucket system.

The final project was putting everything we learned together — this included line following, turning on

intersections, and picking up/dropping items using the bucket and arm system.

Although the tasks seemed simple at first, there were many challenges that required unique solutions

to make the code function correctly. The main problems were traction, battery life, and using open-loop code.

The first and simplest fix: the traction, which became an issue when the wheels became dirty and started slipping on the ground.

As the wheels became more slippery, the code needed to be slightly adjusted

very often to counteract this, so we cleaned the wheels with a toothbrush.

The LiPo batteries were hard to work with, since even if a good battery was used, it would be depleted very quickly. The more they

were used, the less power they gave to the motors and sensors,

which slowed down the bot and changed the timings. Since we were using specific timings for turns, the battery always needed to be fully charged to

be consistent.

This leads into the next problem, which is using an open-loop system — This is where everything the bot does

is based on delays without any feedback from any sensors. Clearly, the solution would be to code in a closed-loop system,

where the bots actions are determined based on sensor readings and feedback.

The challenge with this is that we did not have many sensor options, so we would need to create complex algorithms for some simple actions.

We found a good balance for using open and closed-loop code, and only used open-loop for turns at intersections.

As part of the final submission, each group was required to record a short video of the entire run. If

you want to watch my group's submission, click this link,

turn up the volume and enjoy! (feat. AI Sir David Attenborough)